Mini-lenses are revolutionizing the world of optics and consumer electronics, offering a compact and cost-effective solution for light manipulation. Developed by Rob Devlin during his graduate studies at Harvard, these innovative devices utilize light-focusing metasurfaces made of tiny pillars on a thin wafer, allowing for efficient light bending without the bulk of conventional lenses. Since the founding of Metalenz in 2016, demand for mini-lenses has surged, leading to the production of millions for various electronic applications. By integrating advanced polarization technology into their designs, Metalenz ensures these mini-lenses not only enhance device aesthetics but also improve functionality, crucial for modern smartphones and tablets. This breakthrough in optical engineering exemplifies how cutting-edge research can drive consumer electronics innovations forward.

The emergence of micro-optical components, often referred to as micro-lenses or metasurfaces, is reshaping how we perceive and utilize light in technology. These ultra-thin devices, pioneered by researchers such as Rob Devlin from Metalenz, harness advanced light manipulation techniques to optimize performance in consumer gadgets. With the integration of polarization methods, these micro-lenses bring unparalleled efficiency and compactness to everyday devices. As the tech industry pushes for sleeker designs with enhanced photographic capabilities, the development of such advanced optical components represents a significant leap forward in consumer electronics. The evolution of these innovative lenses not only opens new avenues for visual quality but also sets the stage for exciting advancements in security and beyond.

The Revolutionary Impact of Mini-Lenses in Consumer Electronics

The advent of mini-lenses, particularly those developed by Metalenz, has revolutionized the landscape of consumer electronics. Traditionally, optical components such as cameras relied heavily on bulky glass or plastic lenses, which posed significant limitations in terms of size, weight, and design flexibility. By utilizing light-focusing metasurfaces made up of tiny pillars on a wafer, Metalenz has successfully launched products that not only meet consumer demands for sleek design but also enhance the performance of devices like smartphones and tablets. This innovation allows for a significant reduction in physical space, enabling manufacturers to integrate advanced features into devices without compromising on aesthetics or functionality.

The extensive application of these mini-lenses in devices such as iPads and Galaxy smartphones has marked a notable shift in how we perceive and utilize technology in our daily lives. As Rob Devlin, CEO of Metalenz, points out, the ability to produce millions of these metasurfaces has made a profound impact not only on the functionality of devices but also on the overall user experience. By merging advanced optical technologies with cost-effective manufacturing techniques, Metalenz is poised to lead the charge in the next wave of consumer electronics innovations, truly embodying the convergence of cutting-edge science with practical use.

Metalenz: Bridging Academic Innovation and Market Reality

Metalenz’s journey from a Harvard lab to a global player in the optics industry exemplifies the successful transfer of academic research into viable commercial products. Under the guidance of pioneers in light-focusing metasurfaces, Rob Devlin and his team have turned groundbreaking research into practical applications that cater to modern technological needs. The supportive ecosystem created by Harvard’s Office of Technology Development has been pivotal in nurturing the growth of startups like Metalenz, which leverage cross-disciplinary expertise to disrupt conventional markets. The findings from Capasso’s lab not only validate the scientific principles of metasurfaces but also demonstrate their practical impact on existing industries.

As Metalenz continues to scale, it serves as a shining example of how university research can lead to the creation of completely new industries. By breaking away from traditional lens design and focusing on innovative solutions like mini-lenses, the company exemplifies how cutting-edge research can address real-world challenges. This strategy of innovation not only enhances the capabilities of consumer devices but also paves the way for future advancements, creating a ripple effect throughout the tech industry. With products that hold promise in applications as diverse as AR technology and advanced facial recognition, Metalenz is redefining the possibilities that arise from university-led innovation.

Transforming Optical Capabilities with Polarization Technology

Polarization technology is rapidly emerging as a game-changer in consumer electronics, and Metalenz is at the forefront of this transformation. The introduction of Polar ID technology—a compact and cost-effective solution for increasing smartphone security—highlights the profound potential of polarization metasurfaces. Traditional polarization cameras can be unwieldy and prohibitively expensive for mass-market applications. In contrast, Metalenz has developed a device that is only 5 millimeters long and priced at around $5, making significant strides in accessibility and scalability for various consumer applications. By leveraging the unique polarization signatures of individuals, Polar ID not only enhances security measures but also expands the utility and functionality of personal devices.

Moreover, the implications of polarization technology extend beyond security. Innovations in medical diagnostics through skin cancer detection epitomize the diverse applications made possible by these advanced sensors. The ability to differentiate between healthy and unhealthy tissue using polarization is a revolutionary step forward and could lead to earlier detection and treatment for various conditions. Therefore, as Metalenz fine-tunes its products, it is not just setting the stage for enhanced functionalities in consumer electronics but also contributing significantly to healthcare advancements, demonstrating the multifaceted potential of these new technologies.

The Future of Metasurfaces: A Continuous Journey of Innovation

Looking ahead, the future of metasurfaces is anchored in continuous innovation and refinement. Metalenz is committed to not only maintaining its lead in the market but also pushing the boundaries of what light-focusing metasurfaces can achieve. With ongoing research and development, the company aims to explore new functionalities that integrate their technology into emerging applications, thereby securing their position as leaders in the optics industry. The collaboration with esteemed figures like Federico Capasso ensures that Metalenz benefits from cutting-edge research, creating a robust pipeline for future innovations that promise to enhance performance across a wide spectrum of electronic devices.

In a landscape characterized by rapid technological advancements, the challenges posed by competitors are ever-present. However, the strong foundation established by Metalenz, founded on years of rigorous academic research, positions it well for sustained growth and innovation. By focusing on product enhancement and the development of new features, the company is poised to integrate disruptive technologies into everyday devices, ultimately altering the way consumers interact with technology. The commitment to innovation and the ability to leverage unique aspects of metasurfaces will play a crucial role in shaping the future of consumer electronics, creating a pathway for advancements that will continue to improve lives.

Rob Devlin: Visionary Leader Shaping Tech Innovation

Rob Devlin’s leadership at Metalenz is a driving force behind the company’s success in the consumer electronics sector. As a visionary who has combined his academic background with entrepreneurial spirit, Devlin exemplifies how researchers can transition into industry leaders. His ability to translate complex scientific concepts into marketable products has positioned Metalenz at the forefront of optical technology innovation. His perspective on utilizing light-focusing metasurfaces to optimize device functionality resonates with a broader vision for the future of tech, where performance and efficiency reign supreme.

Devlin’s insights into the competitive landscape underscore the importance of innovation in maintaining a leading edge. He recognizes that while others may follow, the rapid deployment of their technology has set Metalenz apart. Drawing on robust academic research and unique perspectives garnered from diverse fields, Devlin’s approach facilitates a culture of constant improvement and forward-thinking that is essential in the fast-paced tech arena. In shaping the dialogue around the future of optics and consumer electronics, his contributions are paving the way for breakthroughs that extend far beyond conventional understandings.

Academic Roots: The Backbone of Metalenz’s Success

The journey of Metalenz is a testament to the power of academic research as a catalyst for innovation. Federico Capasso’s work on light-focusing metasurfaces laid the foundation for a groundbreaking change in optical engineering, emphasizing the potential for academia and industry collaboration. This synergy has allowed for the exploration of novel materials and techniques that would have otherwise remained confined to theoretical discussions. The insights gained from rigorous research translate into practical applications that redefine industry standards and consumer expectations.

The commitment to innovation rooted in academic principles has enabled Metalenz to not only develop advanced products but also establish a framework for continuous progress. The focus on rigorous testing, iterative design, and a strong understanding of physics and engineering underpins the success of the mini-lenses being deployed in consumer electronics. As the company grows, the influence of academic rigor will continue to shape its strategies, ensuring that each product rollout is backed by solid research and innovation, ultimately shaping the future of optics in technology.

Metasurfaces: Disrupting Established Industries

The introduction of metasurfaces has initiated a disruption throughout the established optics industry, challenging traditional methods of lens manufacturing and design. Metalenz epitomizes this shift, as their innovative light-focusing technologies enable a new class of optical components that are not only compact but also cost-effective. The transition from bulky glass lenses to sleek mini-lenses is a direct response to the demands of modern consumers seeking portability and enhanced functionality in their devices. By disrupting established norms, Metalenz is redefining what is possible in consumer electronics.

With the continued evolution of technology, the opportunities for metasurfaces are expansive. As manufacturers seek to integrate more features into compact devices, the lightweight and versatile nature of these components offers remarkable advantages. The potential applications extend far into the realms of augmented and virtual reality, where traditional optics could hinder performance. Metalenz’s ability to lead in this space not only reflects their innovative prowess but also signifies a broader shift towards a new era in optical technology, driven by the principles of efficiency, cost reduction, and superior performance.

Collaborations and Partnerships: Fueling Growth

Metalenz’s growth trajectory is significantly bolstered by strategic collaborations and partnerships that unlock new pathways for technological advancement. Collaborating with established semiconductor manufacturers like STMicroelectronics allows for the mass integration of their metasurfaces into innovative modules. The partnership enhances the capabilities of distance-measuring components essential for applications such as facial recognition and augmented reality. By leveraging existing manufacturing processes, Metalenz accelerates its roadmap to delivering breakthrough optical technology to market.

These partnerships are not merely transactional; they embody a commitment to innovation and shared goals. As the demand for efficient and advanced optical solutions continues to rise, strategic alliances with businesses attuned to emerging technology needs create a robust ecosystem for growth. Metalenz’s focus on partnerships emphasizes their proactive approach to addressing market gaps, ensuring their metasurfaces define the future of optics in consumer electronics while fostering a collaborative spirit in a competitive landscape.

Embracing Future Technologies: Metalenz’s Vision

Looking towards the future, Metalenz is poised to embrace technologies that expand the scope and capabilities of light-focusing metasurfaces. As advancements in artificial intelligence and machine learning integrate with optical systems, the potential for next-generation applications is immense. Rob Devlin’s vision for utilizing the unique properties of polarization technology serves as an inspiration for pushing the boundaries of consumer electronics. By innovating in ways that enhance security and enable new functionalities, Metalenz is not only adapting to changing industry demands but also shaping the future of technology.

The integration of future technologies presents a unique opportunity for Metalenz to lead in the optical industry. As consumer preferences shift towards more sophisticated and multifunctional devices, the ability to harness cutting-edge developments will be critical. The company’s commitment to research-driven innovation, along with a keen awareness of market trends, enables them to spearhead advancements that will redefine user experience across every facet of consumer electronics. As they embrace the future, Metalenz continues to exemplify the fusion of science, technology, and responsive design.

Frequently Asked Questions

What are mini-lenses and how do they differ from traditional lenses?

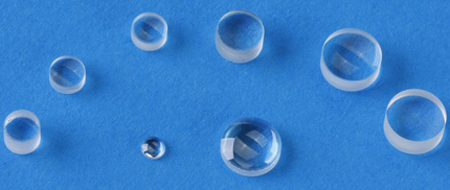

Mini-lenses, also known as light-focusing metasurfaces, utilize advanced nanostructures instead of traditional curved glass or plastic elements to manipulate light. This technology allows for significantly thinner and lighter lenses, making them ideal for modern consumer electronics.

How are mini-lenses revolutionizing consumer electronics?

Mini-lenses are revolutionizing consumer electronics by reducing the size and cost of optical components while enhancing performance. Companies like Metalenz have successfully integrated these light-focusing metasurfaces into devices such as smartphones and tablets, enabling innovative features while saving space.

What role does Metalenz play in the development of mini-lenses?

Metalenz, co-founded by Rob Devlin, specializes in the mass production of mini-lenses. The company has commercialized the technology developed in the Harvard Capasso lab, producing millions of mini-lenses used in various consumer electronics, thus transforming the traditional optics industry.

What is the significance of polarization technology in mini-lenses?

Polarization technology is pivotal in mini-lenses, particularly for applications like security and health monitoring. Metalenz’s Polar ID uses light polarization to offer enhanced security features in smartphones, demonstrating the potential of mini-lenses in creating novel functionalities beyond conventional imaging.

How do mini-lenses improve depth sensing in devices?

Mini-lenses enhance depth sensing by enabling precise light control, which is crucial for 3D sensing applications. For example, STMicroelectronics employs metasurfaces in their FlightSense module, allowing devices to accurately measure distances using infrared light, which is instrumental in facial recognition and augmented reality.

What advancements can we expect from the future of mini-lenses?

The future of mini-lenses is promising, with ongoing developments aimed at further miniaturization and cost reduction. Innovations like Polar ID from Metalenz illustrate how the technology can be adapted for various applications, including security and healthcare, hinting at a broad spectrum of future uses.

Can mini-lenses be produced at scale and what are their manufacturing costs?

Yes, mini-lenses can be produced at scale thanks to existing semiconductor fabrication methods. Companies like Metalenz are manufacturing millions of these metasurfaces, ensuring that costs remain low—approximately $5 for advanced polarization metasurfaces—making them accessible for widespread use in many devices.

What makes the mini-lens technology developed in the Capasso lab unique?

The mini-lens technology from the Capasso lab is unique due to its innovative use of tiny nanostructures to bend light efficiently, allowing for high-performance optics in a tiny form factor, which traditional lenses cannot match. This approach opens new possibilities in optics, influencing various industries.

| Key Point | Description |

|---|---|

| Introduction to Metalenz | Rob Devlin developed innovative mini-lens technology at Harvard, launching Metalenz in 2016. |

| Mini-lens Technology | The mini-lens uses tiny pillars on a wafer to bend light, offering a smaller, cheaper replacement for traditional lenses. |

| Market Impact | Metalenz has produced over 100 million mini-lenses used in various consumer electronics, including popular devices. |

| Development Timeline | The mini-lens concept evolved from lab research in 2007 to mass production in just a few years. |

| Applications | Used for 3D sensing in devices, aiding in applications like facial recognition and augmented reality. |

| Polar ID Technology | An upcoming product designed to enhance smartphone security through light polarization. |

| Future Prospects | Metalenz aims to innovate further, leveraging partnerships for next-gen applications in health and environmental monitoring. |

Summary

Mini-lenses are revolutionizing consumer electronics by offering advanced optical capabilities in a compact form. The development of mini-lens technology, particularly through the efforts of Metalenz, showcases how academic research can lead to practical applications that disrupt traditional industries. As companies increasingly seek innovative solutions for enhanced functionality, the adoption of mini-lenses in products from major brands signals a transformative shift in how we approach optical engineering, presenting new opportunities across various sectors.